Photo voltaic Cell or PV Cell is a small unit of PV module and the facility output of a single PV cell worth is 0.5V & 10A. If you wish to know the essential building of a PV cell, then we will perceive from the beneath picture. It has two layers – P-N Junction. Unfavorable layer of photo voltaic cell positioned on higher aspect and Optimistic layer on backside. The N-layer is thinner than the P-layer. As we all know, a PV cell is product of silicon (means sand) and a mixture of silicon and carbon, then hit it at 5000 diploma celsius.

Supply: Picture/Battle Born Batteries

After performing some course of, it converts into silicon Ingot. It seems like a sq. formed like bread. After that, the ingot cuts into very skinny items and it makes wafers. It makes polycrystalline wafer after which begins dropping the method of phosphorus and in wafer to extend effectivity of photo voltaic cells. And Lastly, we use these photo voltaic cells in PV module manufacturing.

Step-by-step course of:

| Step 1 | Step 2 | Step 3 | Step 4 | Step 5 |

| Silicon | Silicon Ingot | Silicon Wafer | Photo voltaic Cells | PV Module |

Forms of PV Cells Effectivity Sensible, Worldwide

Within the above part, we learn about photo voltaic cells and its making course of. Now, we learn about what forms of photo voltaic cells obtainable now, so now we have the given PV cells with effectivity:

| Forms of PV Cells | Effectivity |

| Tandem | 29% to 32% |

| HJT | 26.84% |

| TOPCon | 24% |

| MONO PERC | 23% |

| Monocrystalline | 21% |

| Polycrstalline | 16% |

| Skinny movie | 16% |

How do Photo voltaic PV Module Manufactured?

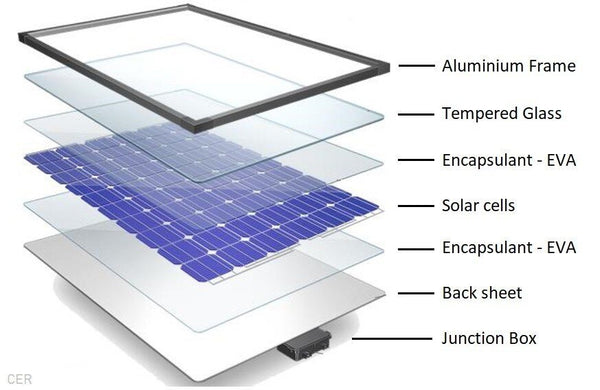

PV module is a set of photo voltaic cells and it’s encapsulated by an aluminum body. Within the picture beneath, you may see one single PV module has 7 layers: glass, body, EVA, cells, junction field with mc4 connector, again sheet, RFID, and extra. Photo voltaic cells are linked in sequence and parallel and closing output connects within the junction field. After we mix multiple PV module then it turns into a Photo voltaic Panel and a number of photo voltaic panels join then it turns into a photo voltaic array and a number of photo voltaic arrays mix then it turns into a solar energy plant.

Supply: Picture/

For instance, if customers set up 5kW solar energy vegetation, then it comes 8 to 10 PV modules and the output energy of 384V to 500V.