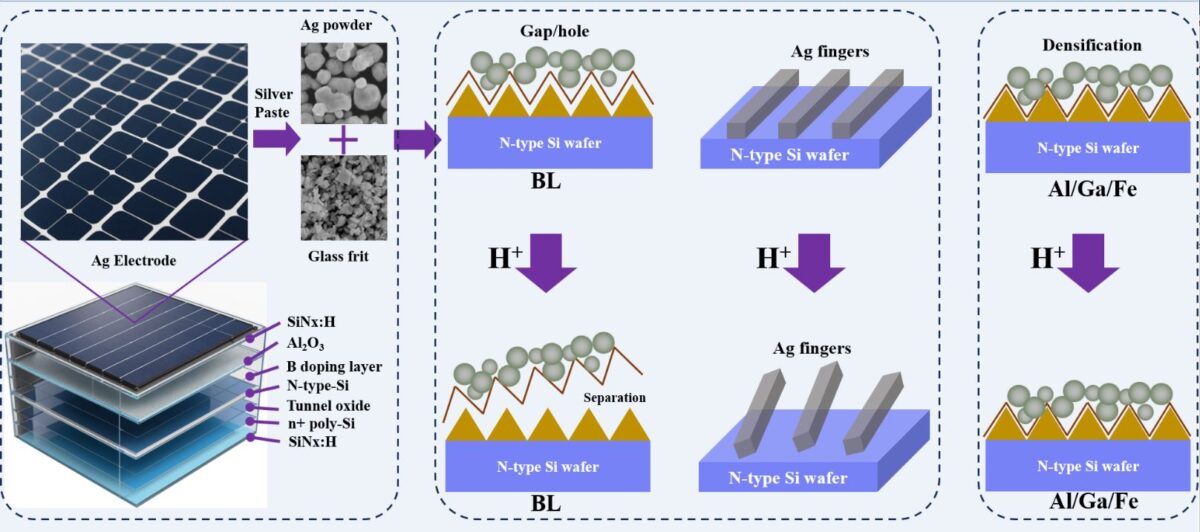

Scientists in China have developed innovative silver pastes for the LECO fabrication of TOPCon solar cells. These new pastes incorporate either aluminum, gallium, or iron and are said to securely bind the cells’ electrodes to the silicon surface due to the improved stability of the lead oxide (PbO) element within the glass powder.

A team spearheaded by the Chinese Academy of Sciences asserts that they have enhanced the quality of silver paste used in the manufacturing of solar cells grounded on tunnel oxide passivated contact (TOPCon) technology through the so-called laser-enhanced contact optimization (LECO) procedure.

This procedure occurs post-firing of the metallization paste and includes scanning a laser over a crystalline silicon cell while it remains under reverse bias. This action compels free carrier electrons to move between the metal contact and the silicon, resulting in a novel arrangement on the outer boundary of the contact and the boron emitter layer surface—a current-fired contact (CFC). Thanks to this new CFC configuration, TOPCon cells subjected to the LECO method exhibit no contact resistivity following thermal cycling.

“There is a pressing need to enhance LECO-compatible silver pastes to guarantee the durability and stability of TOPCon solar cells,” articulated the study’s corresponding author, Jiangtao Di, to pv magazine. “In this study, we focused on optimizing glass formation by incorporating elements such as aluminum, gallium, and iron into the inorganic glass frits of conductive silver pastes.”

The research team formulated new kinds of LECO silver pastes, integrating aluminum (Al), gallium (Ga), and iron (Fe) within the glass frits to assess their acid corrosion stability through a degradation test using acetic acid.

“We evaluated the deterioration of TOPCon solar cells in conventional acetic acid settings,” Di clarified. “The silver paste formulated with glass frits including additional Al, Ga, or Fe elements demonstrated significantly improved resistance to acetic acid corrosion relative to silver paste that lacked these unique elements.”

The investigation indicated that the new glass frits ensured the electrodes of the cells remained securely attached to the silicon surface due to the enhanced stability of the lead oxide (PbO) ingredient in the glass powder.

“The efficiency reduction of LECO-utilized silver paste with Al/Ga/Fe additives during exposure to acetic acid can be under 10%, and as minimal as 5%,” Di continued. “Conversely, without the incorporation of these unique elements, the corrosive impact of acetic acid can rise sharply to over 50%.”

“Our research provides highly dependable LECO-compatible silver pastes for TOPCon solar cells,” he concluded.

The outcomes of the research are accessible in the publication titled “Enhancing TOPCon solar cell reliability via Al/Ga/Fe-added glass frits in LECO-compatible silver pastes against acid corrosion,” recently released in Solar Energy Materials and Solar Cells.

This content is safeguarded by copyright and must not be reused. If you wish to collaborate with us and would like to reuse some of our material, please get in touch: editors@pv-magazine.com.