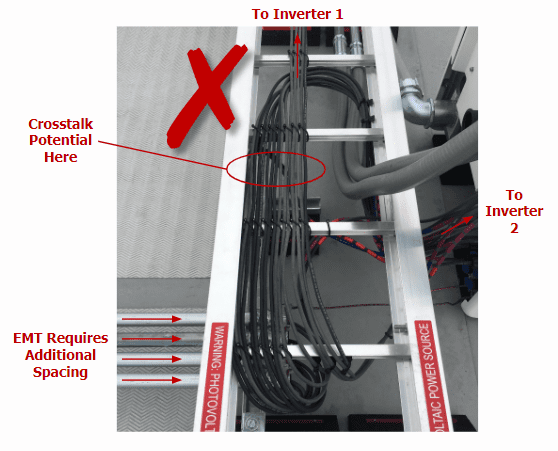

Image this. You’re a seasoned solar PV installer and also have actually been consisting of component degree power electronic devices (MLPE) as component of tiny and also domestic business systems for several years. Today you’re appointing a brand-new roof job for the biggest business customer you have actually needed to day, and also you’re delighted to make an excellent perception. It’s a brilliant warm day, and also the devices looks effectively set up– however when you transform it on, the tracking reveals no electrical energy being created. Also after three-way and also dual inspecting your links, the issue is not evident. Your customer is touching his watch. What do you do? When conductors attached to various inverters are not effectively spaced apart,

Crosstalk is a possible problem.

MLPE “crosstalk” is not the only problem that can show up on appointing day, however it is a specifically refined one. Solutions struggling with crosstalk typically will certainly not also switch on. Sometimes, crosstalk triggers your MLPE tools to calmly switch over quickly on and also off, shedding them out promptly, and also developing prospective dangers. Repairing crosstalk concerns typically entails transforming cord runs, so resolving it after setup can be taxing and also pricey. With some planning, it is simple to prevent this problem totally.

To comprehend crosstalk, one need to take into consideration exactly how MLPE obtains and also sends out interaction signals for fast closure, and also possibly for various other features. Signals need to be traded in between the MLPE and also a main control gadget, typically situated within the inverter. While some MLPE items can interact over Wi-fi, this does not constantly deal with bigger jobs where the signal need to be trusted over big ranges.

If you’re fretted that the constraints of Wi-fi can just relapse by including committed interaction lines, fret not. A effective and also glossy choice called high-voltage line interaction (PLC) sends out information over the PV power conductors themselves. Numerous MLPE items capitalize on PLC, and also it can create a tidy and also cheaper setup. When several stimulated circuits bring a PLC signal are transmitted with each other via avenues, rain gutters, or wire trays,

Concerns can develop. The signal from one PLC transmitter can be detected neighboring conductors via electro-magnetic induction, developing sound and also interfering with interactions. Have you ever before been paying attention to a radio terminal in your cars and truck, and also as you enter the countryside, a brand-new terminal begins to repeat the one you’re paying attention to? You were shaking out, now Johnny Cash money is singing Baritone over your Led Zeppelin. The very same point can occur with MLPE interaction signals on cords existing straight next to each various other! This is what crosstalk is; the service is as basic as maintaining your stimulated circuits different.

Exactly How do you do this in technique? It will certainly differ based upon the certain MLPE and/or inverter made use of. Various items interact in a different way, and also it is necessary constantly to check out the guidebook of the devices with which you’re functioning. Suppliers might have described guidelines on avoiding PLC crosstalk, which must come before any type of basic info we give below. In this write-up, we’ll consider exactly how Tigo optimizers make use of PLC and also prevent crosstalk.

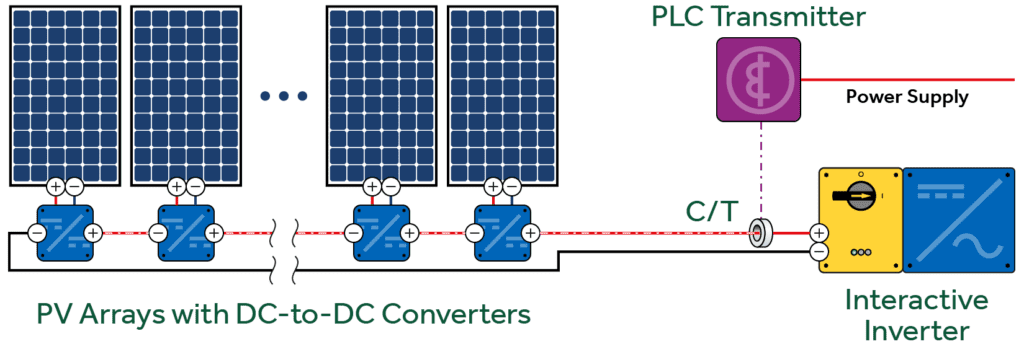

In one instance, we have a tiny system with one string of components plus Tigo optimizers feeding a solitary inverter. A Tigo PLC transmitter is put near the inverter to regulate a signal on the PV circuit. When a grid failure happens, this makes certain fast closure of the optimizers. This “inflection” is a tiny (low-amplitude) data signal positioned on top of the dc voltage from the solar components. When they can spot the signal from the PLC transmitter, Tigo RSD MLPEs just permit PV voltage onto the circuit. When the grid decreases, the PLC signal stops, and also each optimizer will certainly likewise stop PV manufacturing.

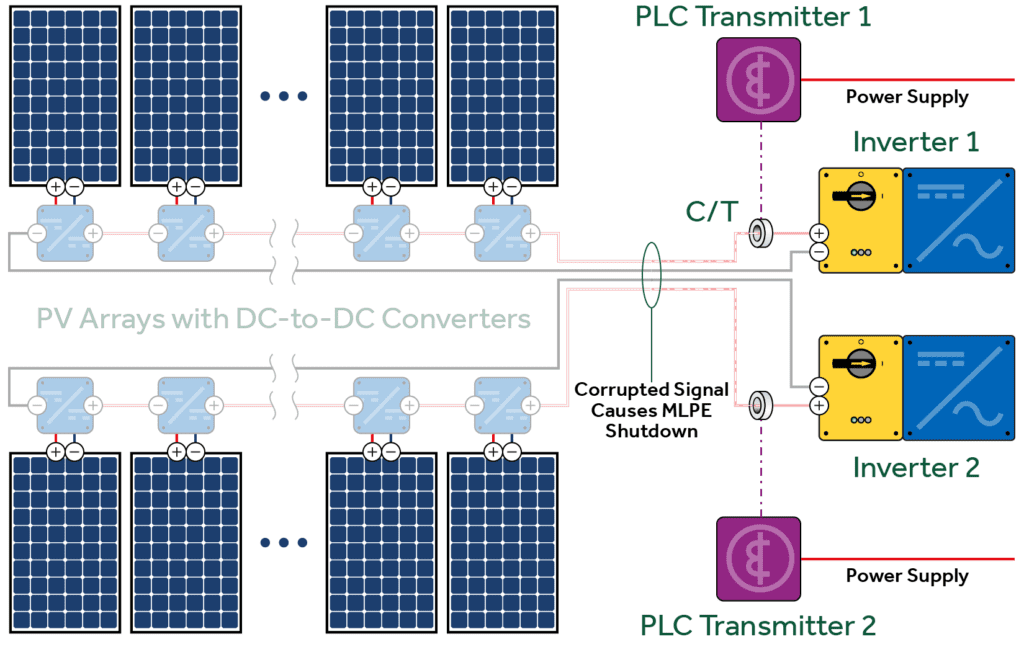

One Tigo PLC transmitter can include the interaction signal onto an optimum of 10 PV circuits. When you have even more than 10 PV strings or several inverters, you’ll require to include one more transmitter. When cords bring signals from various transmitters lay near one an additional, Crosstalk is just turbulent. That suggests that with Tigo optimizers you can have up to 10 PV strings and also a solitary transmitter without having any type of crosstalk concerns. If your system makes use of several PLC transmitters, the circuits linked with each transmitter should be divided throughout their whole run. Tigo advises a minimal range of 8 inches in between cord runs when utilizing their item, however this will certainly differ for various other producers.

Some producers might have means to decrease also better the variety of different cord runs called for in your system style. Tigo, as an example, has an ingenious attribute called Pure Signal that enables approximately 10 transmitters to sync with each other. The interaction in between the transmitters preserves a constant signal throughout all circuits. By daisy chaining the transmitters with each other, the PV outcome circuits from approximately 10 inverters can after that be transmitted with each other without creating crosstalk concerns. You need to divide any type of PV circuits bring unsynced PLC signals if your job has over 10 inverters.(*) Having different runs for the PV circuits bring various signals includes the expense of added channel and also labor, and also takes extra physical area. This included intricacy is counterproductive to numerous developers– and also clients– it is vital for the risk-free and also correct performance of MLPE systems that interact making use of PLC. Make the effort to analyze crosstalk from the beginning of your job, and also you’ll thank on your own later on.(*)