By Khushboo Goyal

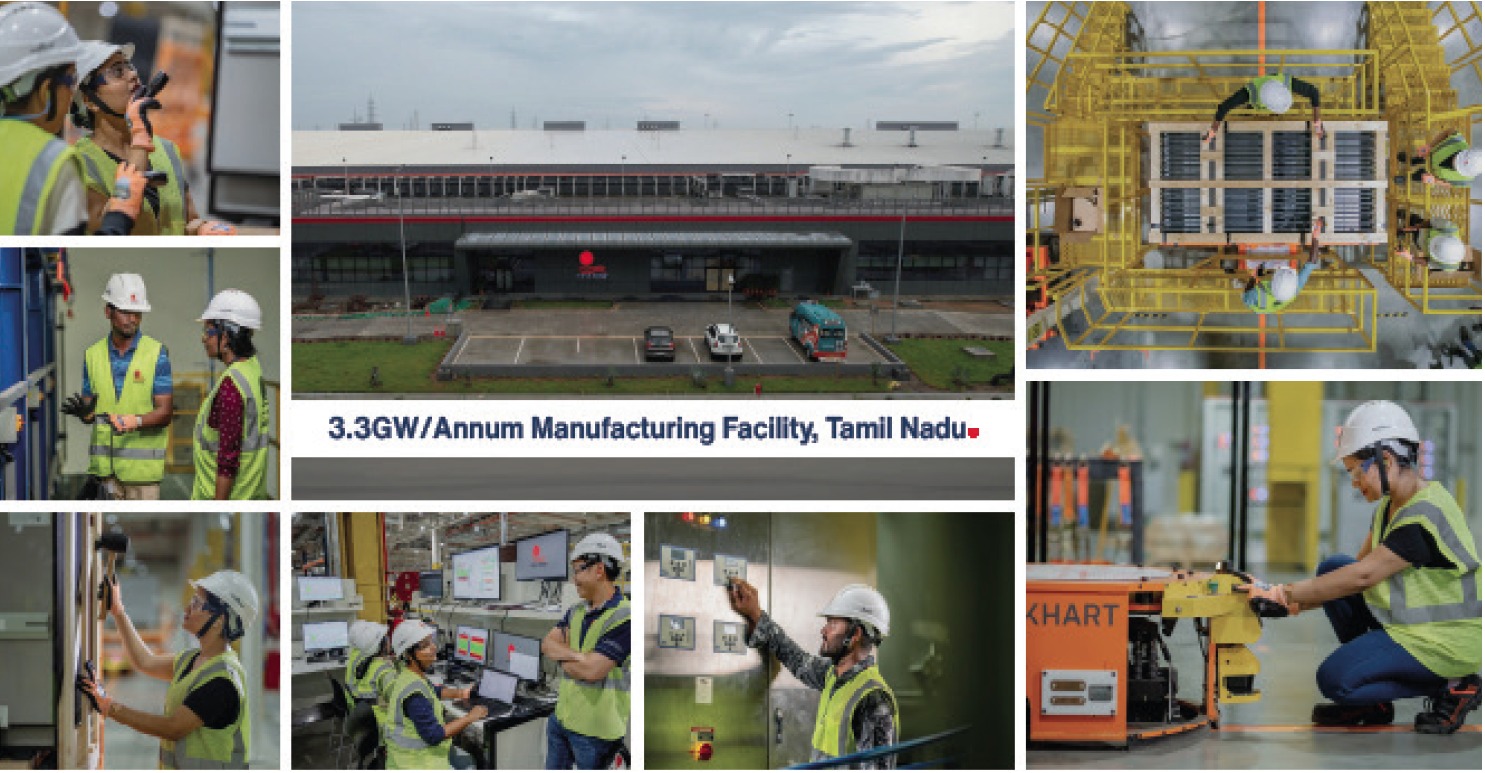

First Solar, based in Arizona, initiated its first solar manufacturing facility in India in 2023, showcasing an impressive yearly production capacity of 3.3 GW. The firm specializes in thin-film solar panels, setting it apart from numerous competitors that concentrate on crystalline technology. Remarkably, First Solar is the only substantial solar producer from the Western Hemisphere, particularly the United States, to set up a module manufacturing site in India. It has received recognition under India’s Production-Linked Incentive (PLI) scheme Tranche-II and is the sole foreign participant selected for this program, establishing its operations in Sriperumbudur, close to Chennai, Tamil Nadu. The facility has been added to the Approved List of Models and Manufacturers (ALMM) by the Ministry of New and Renewable Energy, qualifying it for Domestic Content Requirement (DCR) solar initiatives, and producing its Series 7 solar modules on-site.

During my trip to the facility in Chennai, which covers a floor space of 2.5 million square feet, I was thoroughly guided by Sujoy Ghosh, Vice-President and Country Managing Director, India. Our discussions encompassed thin-film technology, the facility’s environmental initiatives, and First Solar’s international operations, as well as insights into the strategic selection of Chennai as a manufacturing center and the essential nature of supply chain sustainability within India’s solar sector. This article presents a summary of First Solar’s global operations, followed by specific insights regarding the Indian plant, including its execution and efforts in environmental sustainability.

Background

First Solar was established in 1999, with its initial production line launching in Ohio in 2003. The enterprise currently holds an aggregate nameplate capacity of 21.7 GW annually, with manufacturing facilities located in the United States, Malaysia, Vietnam, and India. The corporate headquarters is situated in Tempe, Arizona, complemented by R&D centers in Santa Clara, California, and Sweden. Although the company formerly operated a factory in Frankfurt Oder, Germany, it was shut down in 2012 due to unfavorable market conditions influenced by the influx of solar panels from Chinese manufacturers.

While crystalline solar technology predominates the current market, there has been an observable increase in demand for thin-film technology. This development has been spurred by the persistent necessity for diversified supply chains, particularly following disruptions occasioned by the COVID-19 pandemic and the widespread dumping of solar cells by Chinese firms. Despite China’s extensive dominance over global polysilicon production—key for crystalline cells—First Solar does not depend on a singular nation for raw materials, utilizing cadmium and tellurium sourced from zinc and copper ores, respectively.

The transition toward diminishing reliance on Chinese imports has prompted multiple nations, including the United States and India, to impose trade restrictions that favor local production. This scenario has been advantageous for First Solar, which has recently broadened its manufacturing operations with new establishments in Alabama and Louisiana, alongside the Tamil Nadu facility, striving to achieve a production capability of 25 GW by 2026, in response to the rising demand for thin-film technology.

The Chennai Facility

The Chennai manufacturing establishment was erected within a 19-month time frame, with its official launch occurring in January 2024. The facility commenced sales in November 2024 after securing necessary local certifications, including BIS. Supported by the Indian government’s PLI scheme, the project also received $500 million financing from the U.S. International Development Finance Corporation (DFC), contributing to a total investment of approximately $700 million. The Tamil Nadu state government significantly aided the project by fast-tracking permits (granted within 35 days) and providing essential utilities, such as high-voltage power and water connectivity, promptly.

Ghosh highlighted numerous considerations influencing First Solar’s decision to establish operations in Tamil Nadu and Chennai. Proximity to seaport transport was vital, enabling the company to import certain glass necessities; three ports are situated within a 40-50 km range. Tamil Nadu also offers a substantial land bank, a stable industrial policy, and established industrial clusters, including a local supplier for its glass requirements, St. Gobain. Furthermore, the project site was pre-approved for red category industries, and the state boasts a well-developed network of engineering colleges to facilitate recruitment efforts, aligning with the initiative of achieving gender diversity in the workforce.

This facility is remarkably the world’s first solar module manufacturing unit to reach net-zero water withdrawal, relying exclusively on treated water from Chennai’s Metrowater TTRO plant, processed via reverse osmosis. It is designed as a zero-wastewater discharge facility and includes a solar recycling plant. The facility employs closed-loop semiconductor recovery technology to recycle cadmium and tellurium from scrap modules, alongside established recovery processes for materials like aluminum and glass.

To align with its sustainability objectives, First Solar has collaborated with Cleantech Solar to acquire 7.3 GWh of renewable energy from an upcoming solar-wind hybrid project in Tamil Nadu. First Solar will hold a 26% equity interest in this captive power initiative, which aims to fulfill 50-70% of the factory’s energy needs through a 15-year power purchase agreement signed in January 2024.

Key Takeaways

The visit provided significant insights into this expansive solar production facility, which encompasses 130 acres, with 33% allocated as green cover. The manufacturing area spans approximately 2.5 million square feet, featuring a fully automated production system that eliminates manual handling of the panels, including packaging.

According to Ghosh, the conversion duration for a sheet of glass into a finished module is 4.5 hours, with a module completed every five seconds. Observing the production workflow, we tracked the module’s passage from raw glass to final packaging along a 4.5 km conveyor system.

As India prioritizes energy security by minimizing imports and promoting local clean energy manufacturing, First Solar’s 3.3 GW facility addresses several key objectives. Notably, the company operates autonomously from Chinese imports for solar module production. It partners with manufacturing allies to co-develop process equipment, fostering a controlled ecosystem. Furthermore, First Solar concentrates on localizing its supply chain for associated components, motivating global suppliers to establish operations in India or form collaborations with domestic suppliers. Ultimately, the company adopts circular economy principles, emphasizing recycling, renewable energy procurement, and sustainable water practices, thus establishing a benchmark for future clean energy manufacturing in India and supporting the nation’s sustainable manufacturing growth.