There was a range of discussion from university student as well as trainers on SEI’s school worrying lithium battery recycling. SEI’s Laboratory Manager as well as Instructor, Alex Jahp, remained in a setting to place jointly some information for our university student as well as workers on the topic. Alex began his picture electronic career with SEI programs in 2015 as well as currently, since the Paonia Laboratory Manager, everyone make money from his continual researching as well as thoughtful involvement with picture electronic knowledge. This short-lived introduction of the state of lithium (Li-ion) battery recycling, procedures, as well as borders to scaling will ideally lead to added discussion of sustainability in picture electronic as well as a boosted understanding of very easy approaches to deal with the rapid impact of the human varieties.

Supply: ReCell Heart

State of Lithium Recycling

Li-ion battery recycling is extremely important to undermine mining within the vigor change as well as make certain the adequate schedule of materials eventually. A whole lot has actually been produced from just how the change to eco-friendly vigor isn’t unskilled as an outcome of it need to need significant mining to offer the minerals to provide PV components, batteries, wind generators, as well as several others. Factors to consider concerning marketing as well as purchasing one unsustainable routines for another, i.e. fossil fuel removal for unusual planet mining, are trusted, nonetheless the amount of materials desired as well as interruption needed for eco-friendly vigor production fades contrasted each of vigor generated on the other hand with fossil fuel burning. Coal power production needs 2,000 circumstances added products go into by weight than picture electronic age to provide the similar amount of vigor 1

Right now, less than 1% of lithium that’s used in batteries is reused as well as as a result, less than 1% is consisted of in brand-new product 2 Commonly, the key objective of Li-ion battery recycling has actually been the reconstruction of cobalt, because of its too much well worth. Every component else has actually been additional. There’s a differ of Li-ion battery reusing procedures with numerous end results. Training course of aspects might be blended in countless approaches, depending on parts like quantity as well as qualities of the material easily accessible, as well as the well worth of the materials that might be recuperated 3

Pyro Training Course of Recycling (smelting)– least expensive cost of material recycling

Pyro Training Course of Recycling (smelting)– least expensive cost of material recycling

Pyrometallurgy utilizes too much temperature levels to promote the oxidation as well as discount rate responses throughout which change steels like Carbon monoxide as well as Ni are reduced from oxides to steels, as well as recuperated in a combined metal alloy. The steels can after that be divided (by hydrometallurgy) as well as utilized to make brand-new cathode products. Various materials along with anode, electrolyte, as well as light weight aluminum are oxidized within the smelter, providing fuel for the approach. The light weight aluminum as well as lithium oxides discover on your own within the slag as well as must not commonly recuperated 3 Whereas effective, this strategy in some cases entirely recuperates 40 to 50 p.c of the materials, omitting the graphite, light weight aluminum, lithium, as well as plastic furthermore existing in batteries 4

Hydro Training Course of Recycling (seeping)– tool cost of material recycling

Hydro Training Course of Recycling (seeping)– tool cost of material recycling

Hydrometallurgy utilizes acids to liquify the ions out of a steady similar to the cathode, creating a mix of ionic varieties within the resolution. These might be recuperated by rainfall or solvent removal as well as responded with various recuperated materials to provide brand-new cathode products 3 When blended with straight recycling

4

, this program of can be used to obtain much better approximately 80-100% of materials.

, this program of can be used to obtain much better approximately 80-100% of materials.

Straight Recycling (physical deconstruction)– greatest cost of material recycling

Straight reusing divides the totally various aspects of the black mass (dynamic products powder from the shredding of cells) by physical procedures, like gravity splitting up, which improve apart materials with out bring upon chemical alterations, allowing the reconstruction of cathode products that’s recyclable with marginal treatment.

Reusing Li-ion Batteries in The United States And Canada

There’s a whole lot to be checked out right below. Simply specifying that reusing features exist does not indicate that the concern is being appropriately dealt with by the non-public market or the federal government. There are great deals of concerns to consider: Are these features easily accessible for people operating in small vigor storage space or just large Electric Auto (EV) manufacturers or energy storage space? What’s the rate of reusing a battery? Just how can we deliver utilized Li-ion batteries? What’s the rate of shipment? Exists any type of worth gone back to the certain individual bringing within the battery? Can a center take care of all codecs as well as chemistries? Varying from the beginning The EPA suggests the following for reusing EV as well as Vigor Storage Space (ES) batteries

- 5

- :

Vehicle: Call the vehicle salvage, shop or distributor lawn the area the battery was gotten. Vigor Storage Space: Call the vigor storage space devices manufacturer or company that placed in the battery The area would potentially these batteries discover on your own? In feedback to USGS, concerning 25 companies in The United States and Canada as well as Europe reuse Li-ion batteries or strategy to act

Redwood Materials 6

Li-Cycle Listed here are a number of such companies:

- can program of 6 GWh of end-of-life batteries, adequate to create higher than 60,000 EVs, yearly. This quantity stands for the large bulk of the Li-ion batteries reused in The United States and Canada today, as well as Redwood is increase their ability to prepare for larger battery quantities as the key wave of EVs retire. Redwood recuperates higher than 95 p.c of the steels (along with nickel, lithium, copper, as well as cobalt) from these batteries as well as utilizes the steels to remanufacture anode as well as cathode aspects. Redwood after that supplies these aspects once more to united state battery cell manufacturers with out the steels ever before leaving the country. By 2025, Redwood Products will certainly increase copper aluminum foil anode as well as cathode production to 100 GWh annual– adequate for 1 million EVs a year– standing for the key time these necessary materials have actually been produced within the united state

- is a Canadian lithium reusing company functioning within the United States with areas in New york city as well as Arizona that might take care of larger batteries along with EV batteries. Li-Cycle states:

- All chemistries as well as codecs of lithium-ion batteries are ideal for our knowledge

Ascend Elements Recover as long as 95% of all basic materials existing in lithium-ion batteries.

No production of land fill waste throughout the program of.

goes to existing building what’s prepared for to be the greatest Li-ion battery reusing center within the united state Situated in Georgia, the capability prepares to return 100% of battery dynamic materials once more right into the schedule chain.

Barriers to Li-ion Battery Recycling

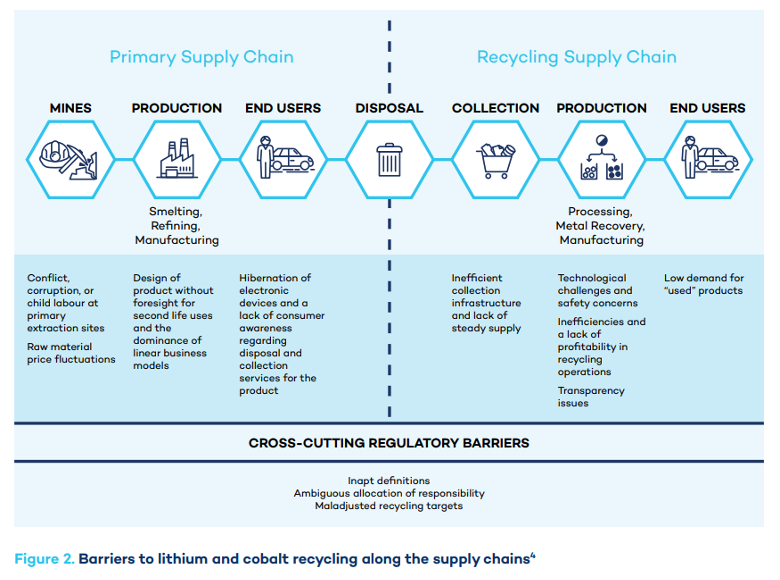

Barriers to reusing feed on each the very first products offer chain element as well as the reusing offer chain element. It appears like the greatest factors are developing the waste diversion facilities as well as building features that might reuse products of appropriate excellent quality for usage in brand-new product; hence, shutting the loophole. Policy is most likely going wished to make this happen.

Supply: “Sustainability as well as 2nd Life: The situation for cobalt as well as lithium recycling,” (Church & & Wuennenberg, 2019)

Recommendations to Remove Obstacles as well as Advertise Li-ion Battery Recycling

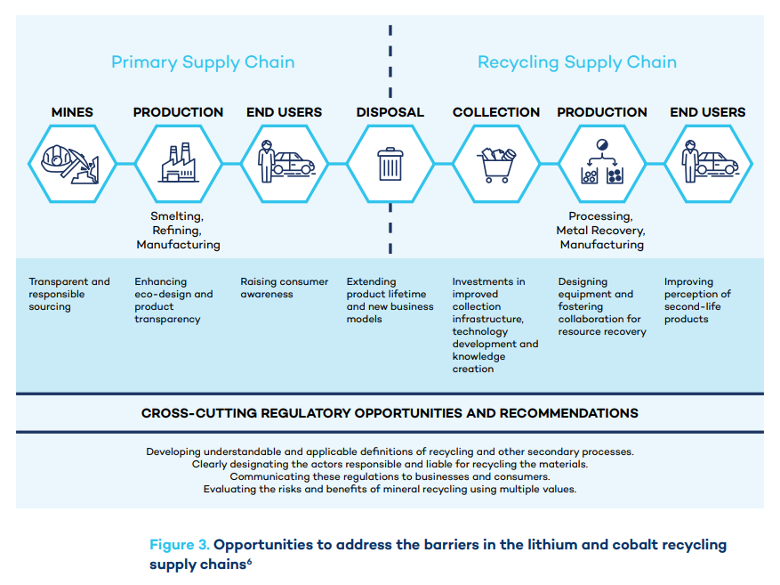

Analyze the visuals under to see every one of the approaches to eliminate borders as well as advertise li-ion battery recycling.

Supply: “Sustainability as well as 2nd Life: The situation for cobalt as well as lithium recycling,” (Church & & Wuennenberg, 2019)

Within the Meanwhile …

Picture electronic Ahead supports the proverb, “downsize, after that generate,” as an outcome of it advertises basically one of the most economical as well as cost-efficient procedure for preparing a modification to eco-friendly age: lessening vigor deepness. Basically one of the most powerful a component of this evaluation as well as the ongoing Li-ion battery discussion among SEI’s university has to do with efficiency, lifestyle alterations, as well as whether altering a burning engine with an electric vehicle really resolves the concern of sustainability writ enormous.

It’s established teaching in some circles of the eco-friendly vigor change that batteries are the most effective means as well as the sunlight for making the adjustment from burning. The press to excite all the important things is struggling below the concept that the all new tons may be transformed with eco-friendly vigor as fossil fuel power is retired. Just how soon as well as efficiently we have the ability to acquire that eco-friendly vigor release is the all new objective line. It’s just one element of the trouble with which people, cultures grapple: As we find approaches to disrupt with previous standards, are we dealing them for added nuanced variants of exploitation as an alternative of analyzing lifestyle alterations that will negate an order within the starting point?

Do you’ve obtained a Li-ion battery you desire to reuse? Inform us the means you do it, that do you call? The area do you deliver it as well as at what rate?[email protected] Do you’re used within the Li-ion battery profession? What do you support individuals finish with their Li-ion batteries on the end-of-life phase?

In situation you are a Picture electronic Ahead team friend, please share your suggestions on Li-ion battery reusing within the Beneficial source Heart Cyber Coffee shop. In situation you are not however a Picture electronic Ahead team friend, after that please obtain bent on

to locate out added.

ResourcesCarbon Tracker Initiative 1

Bond, Ok. (2021, May 10). Mineral restrictions for change overemphasized by IEA. .Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition 2

Hund, Ok., La Porta, D., Fabregas, T. P., Laing, T., & & Drexhage, J. (2020 ). Globe Banks Team.Lithium-ion battery recycling processes: Research towards a sustainable course 3

Gaines, L. (2018 ). 17( C).Sustainability and Second Life: The case for cobalt and lithium recycling 4

Church, C., & & Wuennenberg, L. (2019 ). 68.Used Lithium-Ion Batteries [Overviews and Factsheets] 5

United States EPA, O. (2019, May 16). .

6

USGS. (2022 ). Mineral Asset Summaries 2022 (p. 206). United State Geological Study.

Reducing new mining for electric vehicle battery metals: Responsible sourcing through demand reduction strategies and recycling. Added Researching

- Dominish, E., Florin, N., & & Wakefield-Rann, R. (2021 ).

Institute for Sustainable Futures.Lithium costs a lot of money—So why aren’t we recycling lithium batteries? Discovers the necessary feature that require discount rate approaches as well as reusing can play in lowering the amount of mining called for to release vigor storage space used scientific researches.

- Evergreen, S. (2022, April 19).

Ars Technica.Can We Get Clean Energy Without Dirty Mines? An impressive abstract of the difficulties that exist for lithium battery recycling.

- Pilot, O. (n.d.).

Obtained September 9, 2022.Used EV batteries are storing solar power at grid scale—And making money at it A discussion on the fact of mining, reusing, as well as offer chains connected to the vigor change with Morgan Bazilian.

- Spector, J. (2021, October 18).

Canary Media.ReCell Center A post from Canary Media concerning a company repurposing utilized Nissan Fallen leave batteries for vigor storage space, considering that they may be far from autos when they go to 80 p.c of the distinct ability.

- United State Department of Vigor. (n.d.).

Obtained September 9, 2022.(*) An across the country cooperation of profession, academic community as well as across the country research laboratories functioning jointly to advancement recycling used scientific researches along with all the battery life-cycle for future as well as existing battery chemistries.(*)