Keep in mind that unless or else kept in mind, this post concentrates on photovoltaic panels making use of crystalline silicon (c-Si) cells– without a doubt one of the most usual sort of cell presently utilized in photovoltaic panel production.

It’s not a surprise that as solar PV has actually ended up being mainstream over the previous three decades, renovations in modern technology have actually brought about remarkable gains in the power a solitary photovoltaic panel can generate. What is a shock is that throughout that time, photovoltaic panels’ measurements have not boosted all that much in spite of gains of over 7x in a solitary PV panel’s power outcome. This talks to the realities that:

- Due to the fact that photovoltaic panels are truly simply collections of PV cells, a photovoltaic panel’s power outcome is largely figured out by:

- The number of PV cells the panel has, and also

- The effectiveness of those cells

- A photovoltaic panel’s measurements (physical dimension) are largely figured out by:

- The number of PV cells the panel has, and also

- The dimension of the silicon wafers utilized in those cells

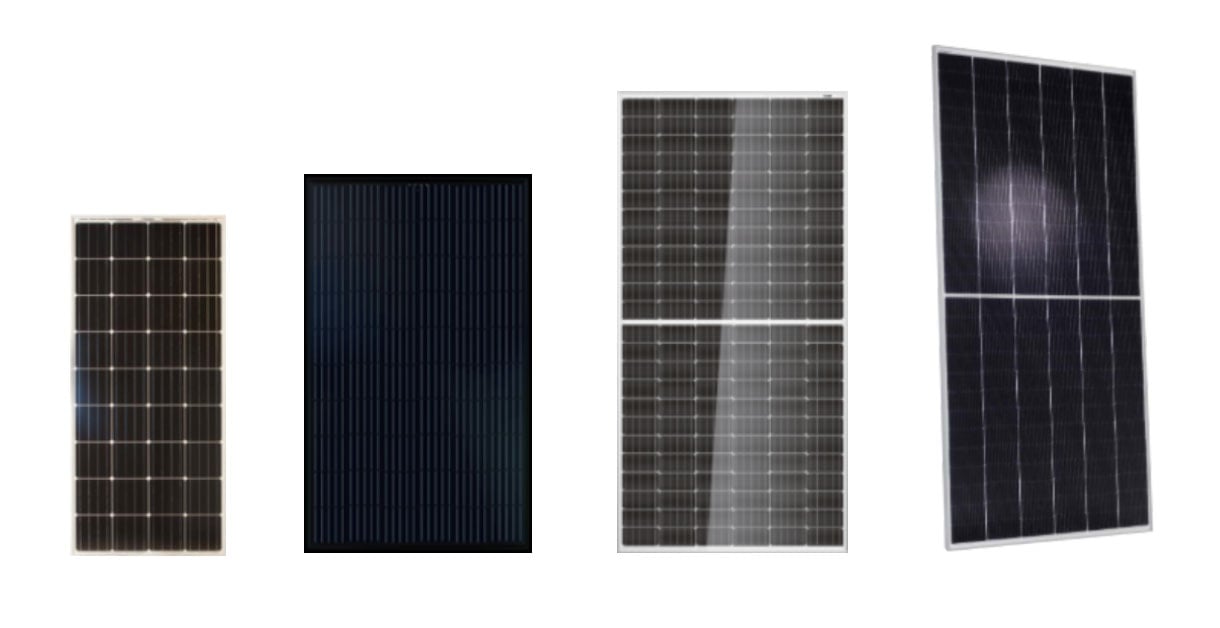

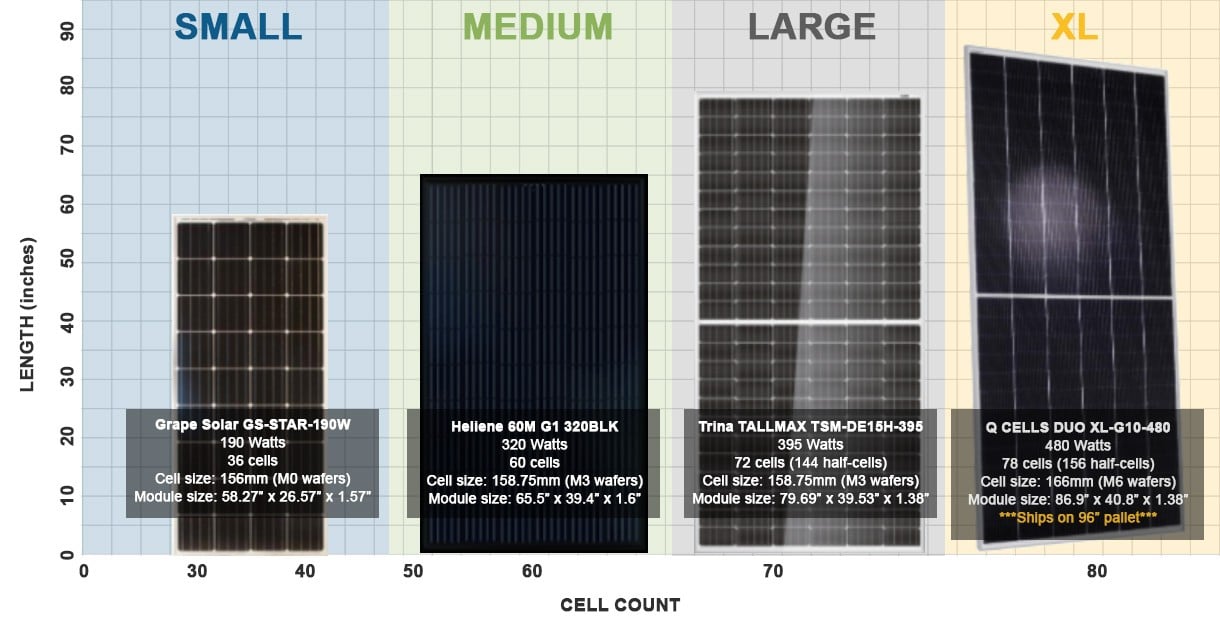

Tiny, Tool, Big, and also Bonus Plus Size Solar Panels

Prior to we obtain as well certain, allow’s obtain common. There are no official meanings or rapid and also difficult regulations around photovoltaic panel dimension and also what makes a certain component “little”, “tool”, “big”, or “additional big.” From a products delivery point ofview, anything over 8 straight feet normally sustains an over-dimension additional charge, so we’re going to make use of that as the limit for “additional big” solar panels. Keep in mind that since we’re discussing delivery below, a thing a little smaller sized than 8 ′ will certainly sustain an over-dimension cost if the pallet it ships on (consisting of the packaging product utilized to safeguard it) steps over 8 ′ (this is exactly the situation with the Q CELLS DUO XL-G10 475/480W components, coming quickly to altE Shop).

Usually talking, this implies that we can consider early-generation photovoltaic panels (which commonly include 36 cells) as “little”, the 60- and also 72-cell components that have actually controlled the market for the last years as “tool” and also “big”, and also components with greater than 72 cells as “additional big”.

Click the picture to increase the size of.

Certainly, there are exemptions to lots of regulations, and also we do have a couple of below. Please keep in mind that:

- Several photovoltaic panels today make use of half-cut cells to minimize repellent power loss and also are commonly marketed as having 120 or 144 cells, however hold still 60- or 72-cell components and also would certainly as a result fall under our tool or plus size groups. …

- Some 72-cell panels making use of M6 or bigger wafers are XL solar panels by our length-based interpretation (see listed below for even more on wafers).

Remarkably, some 96-cell panels are not long sufficient to sustain over-dimension delivery charges since their cell plans are 12 × 8 and also not 16 × 6– suggesting they are not longer than 72-cell panels, simply bigger.

In recap, photovoltaic panels over 8 ′ in size (or panels that deliver on pallets over 8 ′ in size) are thought about additional big photovoltaic panels.

What to Understand About Bonus Plus Size Solar Panels

- Bonus big photovoltaic panels have ramifications for diyers and also installers intending PV systems. Not extremely usual yet, XL dimension solar panels are below to remain. What does this mean for you?

- It is not feasible for a person to mount them– and even relocate them about– without the aid of at the very least another individual. Strategy your installment appropriately!

- It is not feasible to lay them level in a 7 ′ vehicle bed and also have the ability to shut the tailgate.

- They are long sufficient that they sustain an over-dimension charge from a lot of products firms, suggesting delivery is extra costly– specifically when buying in little amounts.

- They are additionally enough time that fork expansions are required to relocate pallets of them with a forklift.

- Their extra weight and also size contrasted to tool and also big panels might need various racking items and also arrangements than you’re accustomed to.

Though the size and also specifically the size measurements are raising, there’s no indicator that the density of components’ frameworks will certainly be raising (and also no factor we ought to anticipate them to), suggesting the exact same widely-available, tried and true photovoltaic panel clamps that have actually gotten on the marketplace for many years will certainly remain to work with additional big photovoltaic panels.

Exactly How Did Solar Panels Obtain so Large?

PV cells’ effectiveness has actually enhanced gradually and also gradually over the last couple of years. In the mid-1990s, effectiveness coming close to 15% went to the reducing side of solar battery modern technology. Today, effectiveness of 29% have actually been attained in lab problems, while numbers in the reduced 20% array are ending up being the criterion for contemporary readily offered components. We are most likely to see even more effectiveness renovations in the coming years prior to the academic effectiveness limitation of single-junction c-Si based cells at around 30% (called the Shockley-Queisser limitation) comes to be a genuine challenge.

Raw silicon is thawed and also formed right into lengthy ingots, which are after that cut right into paper-thin wafers that develop the foundation of solar PV cells.

PV cell effectiveness renovations have actually been available in lots of kinds, however the one pertaining to the physical dimension of the cell is the silicon wafer the cell is constructed around. In the 1980s and also very early 1990s, wafers gauging 100mm square were the common dimension. In the mid-1990s, 125x125mm wafers ended up being the brand-new criterion, and also those were ultimately changed by 156x156mm wafers (which was called an “M0” wafer and also therefore started a brand-new silicon wafer calling convention that presently prolongs completely to 217 × 217 mm wafers understood “M12+”).

In tandem with the rise in solar battery effectiveness (and also dimension), the variety of cells per component has actually additionally boosted gradually. 36-cell components were the very first common dimension, and also are still typically utilized as 12V “off-grid” panels. 60-cell components ultimately ended up being the common and also are still being made today, with 72-cell components ultimately ending up being an added criterion– and also the go-to for utility-scale and also business solar jobs. Today, with customers’ ever-increasing need for electrical power and also step-by-step renovations in solar battery power manufacturing, we are seeing an increasing number of effective panels struck the marketplace. Usually talking, this is a good idea for customers as it can assist in reduced system expenses on points like racking, installing, and also equilibrium of system parts– as long as the boosted expenses of delivery and also labor are meticulously thought about when buying additional big photovoltaic panels

Resources

https://authors.library.caltech.edu/15045/1/JPL-FSA-10-YEARS-OF-PROGRESS.pdf

https://blog.ibc-solar.com/2019/12/from-m0-to-m12-different-wafer-sizes-in-the-market/

https://sinovoltaics.com/solar-basics/solar-cell-production-from-silicon-wafer-to-cell/

https://www.pv-magazine.com/2022/02/15/hanwha-q-cells-begins-selling-its-solar-panels-based-on-m6-wafers-in-europe/(*)