The worldwide change to renewable resource as well as increased use wind power has actually dramatically boosted the variety of wind generators, both onshore as well as offshore. The need for wind generator upkeep is additionally boosting, particularly for vital parts such as transmissions. Borescope evaluations of transmissions are a cost-efficient method to reduce the downtime of wind generators as well as avoid very early discovery of flaws bring about transmission substitute. Since wind generators deal with considerable anxiety as well as wear,

Why wind generators require routine evaluations

Wind wind turbine transmissions, blades as well as generators need extensive upkeep. Keeping these components assists avoid costly fixings as well as downtime. Transmission failings are fairly uncommon (as soon as every one decade usually), yet wind generator downtime can last as long as 6 months while awaiting this component to be fixed.

A regular 2.4-MW wind generator creates concerning $1,000 well worth of electrical power each day, so a several-month downtime can be pricey in regards to shed earnings. Transmission failings can additionally trigger disastrous damages to the transmission, such as a fire because of getting too hot, which might trigger a wind turbine to completely head out of solution.

Benefits of making use of borescopes

The problem of wind generators is generally kept track of making use of managerial control as well as information procurement (SCADA) systems as well as problem surveillance systems (CMS) prior to as well as after evaluations are executed on top of the tower for oil tasting as well as sound checks. SCADA or CMS devices can gather inline resonance as well as oil information from wind generators to identify or forecast blade, primary bearing as well as transmission failings approximately thirty day before the possible failing day.

Nevertheless, SCADA as well as CMS mistake details does not show the precise area of the problem or define the failing problems. Also if you obtain a 30-day caution concerning a transmission failing, your wind generator might be inactive for weeks up until the components get here. Enhancing preventative upkeep methods with remote aesthetic evaluation (RVI) devices that looks inside the transmission can aid determine falling short parts quicker as well as precisely.

With a virtually six-month hold-up in the distribution as well as substitute of specific transmission parts, the earlier the needed component is figured out, the much less downtime the wind generator will certainly have. Furthermore, understanding the condition of possible failings allows you make enlightened as well as aggressive choices concerning components purchase as well as upkeep preparation. Normal borescope evaluations throughout reduced wind period can aid keep an eye on interior transmission degeneration as well as potentially avoid devices failing.

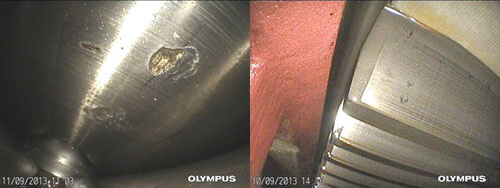

Monitoring photos taken with a borescope or videoscope (an innovative borescope with video clip imaging) assistance determine degeneration as well as flaws in certain places at an onset. Operators can utilize this information to route upkeep tasks as well as component substitute strategies.

Where remote aesthetic evaluation is needed

The inside of the transmission contains a collection of transmissions that transform the low-speed turning driven by the blades right into a high-speed turning that drives the generator. Elements can be harmed by resonance, contaminant blended in lubricating oil or too much anxiety. An aesthetic check of flaws, such as exhaustion, wear, rust as well as cracks, is advised.

The worldly phase bearings as well as worldly equipment supply assistance to the low-speed shaft. The worldly phase soaks up high anxiety from the slow-moving phase in variable climate condition. The framework of the worldly equipment teeth is made complex as well as its area within the transmission makes it tough to accessibility with evaluation devices.

Intermediary phase bearings sustain the intermediary shaft as well as lie at the back as well as the front– straight listed below the various other shafts. Intermediary bearings are tough to examine, primarily because of their area.

High-speed phase bearings are much easier to accessibility throughout an examination yet are more probable to be harmed because of their broadband of in between 1,500-1,800 rpm. This broadband additionally suggests that damages to the high-speed bearings is more probable to influence various other components of the transmission.

Checking with a borescope The worldly phase has 2 worldly service provider bearings as well as 9 round worldly bearings. You can access the worldly phase via little hatches on the blades side of the transmission, normally situated at around the 2 o’clock as well as 10 o’clock placements.

Ring equipment, worldly equipments as well as sunlight equipment: These equipments can be quickly checked with a borescope via the rotor-side hatches. You will certainly wish to examine the surface area problem of their equipment teeth, so a near-focus, forward-viewing videoscope is advised.

Global bearings: String the extent via the room in between the worldly service provider as well as worldly wheel to get to the worldly bearings. Making use of a curved overview tube will certainly aid you avoid the lens from touching the oily surface areas inside the transmission, as well as an oil-clearing lens adapter can additionally boost your sight. Considering that there are 3 worldly wheels, you should turn the blades to access both various other collections of worldly bearings.

Blades side service provider bearings:

Put the extent in between the worldly service provider as well as the transmission’s blades side wall surface to examine the blades side service provider bearings. The generator side service provider birthing evaluation is in some cases tough as it lies much from the front hatch. Attempt the identical phase hatch in addition to the transmission, as some transmissions have a huge opening in between the identical as well as worldly phases. Utilize a lengthy overview tube from the front hatch to get to the generator side service provider bearing if that is difficult. Both identical phases have 3 shafts, each with one round roller bearing as well as 2 conical roller bearings for shaft axial tons as well as advice. You can access the identical phases via the huge hatch in addition to the transmission.

High, low-speed as well as intermediate pinions, equipments as well as bearings: The accessibility hatch in addition to the transmission is huge sufficient to make use of a normal electronic cam to take pictures of these equipments as well as pinions. You require a borescope to examine the problem of the bearings.

High-speed shaft (HSS) bearings: These bearings are normally found near the accessibility hatch in addition to the transmission. You can hold the borescope with your hand to put the extent head in between the roller bearings.

Intermediate-speed shaft (IMS) as well as low-speed shaft (LSS) bearings:

Utilize the accessibility hatch on the top. You will certainly require an overview tube to put the borescope much sufficient to reach them.

- Evaluation suggestions

To carry out a transmission evaluation precisely as well as successfully, choose a borescope with the efficiency as well as features that match the evaluation atmosphere as well as function. When choosing a borescope, take into consideration the adhering to factors.

Clear monitoring also in oily settings

- The devices inside the transmission is covered with lubricating oil. When observing with a borescope, lube commonly enters the optical adapter affixed to the borescope pointer as well as makes the sight uncertain. Assessors can lose fifty percent of their transmission evaluations rearranging the extent as well as cleansing lens. Despite a borescope that does not have a compatible optical adapter, lubing oil sticking to the lens at the pointer of the insertion tube creates the lens to end up being tinted, hindering the monitoring efficiency of the borescope. Consequently, assessors will certainly require to change the borescope or fix.

For That Reason, it is crucial that the borescope utilized for transmission evaluation is immune to lubing oil as well as can avoid oil from sticking to as well as getting in the lens surface area as well as within the borescope pointer.

Photo top quality that makes it possible for discovery of little flaws

- The transmission evaluation needs look for flaws such as scrapes, flaking as well as damages on the bearing surface areas, in addition to flaws such as splits, matching as well as staining of the equipment teeth.

Near-focus monitoring is essential for discovering preliminary flaws on birthing surface areas such as micro-pitting. Deep monitoring of the whole equipment is essential for equipment teeth evaluation. Select a borescope that fulfills both monitoring requires to carry out evaluations successfully.

- Sturdiness ideal for birthing evaluation

Borescope toughness is essential, as damages of evaluation devices throughout transmission evaluation can threaten your wind generator evaluation strategy. Particularly, when evaluating bearings, the borescope is put in the space in between the bearings to observe their surface areas. Physical anxiety has a tendency to be put on the extent insertion tube throughout this evaluation, positioning a danger of damages to the extent expression area. It is advised to select a borescope with a sturdy extent bend.

Made to function inside the constrained nacelle

The room inside the nacelle of a wind generator is slim, so there is minimal room for devices positioning as well as motion throughout evaluations. Select a portable borescope that is very mobile to minimize anxiety throughout job as well as reduce the evaluation time.

Recap

Normal transmission evaluations are a cost-efficient method to reduce the downtime of wind generators as well as avoid very early discovery of flaws bring about transmission substitute.

Normal transmission evaluations are a cost-efficient method to reduce the downtime of wind generators as well as avoid very early discovery of flaws bring about transmission substitute.

The range of wind power generation is anticipated to proceed broadening as need for renewable resource enhances worldwide because of environment modification concerns, the limited nature of geopolitical threats as well as fossil gas. The relevance of videoscopes as well as borescopes will certainly remain to expand for the steady procedure of wind power generation centers.

Junko Uehara has actually held numerous placements supplying remote aesthetic evaluation remedies considering that signing up with the Evident Scientific in 2002. She has experience in worldwide advertising, advertising interactions, as well as videoscopes as well as their applications.

Submitted Under: Included(*) (*)